Character LCD Display Interface

TM4C123GH6PMComplete Lab Manual

For the complete experiment including learning objectives, theoretical background, and detailed explanations, download the PDF manual: Download Experiment 7 PDF

Examples

Example: Basic LCD Driver Implementation

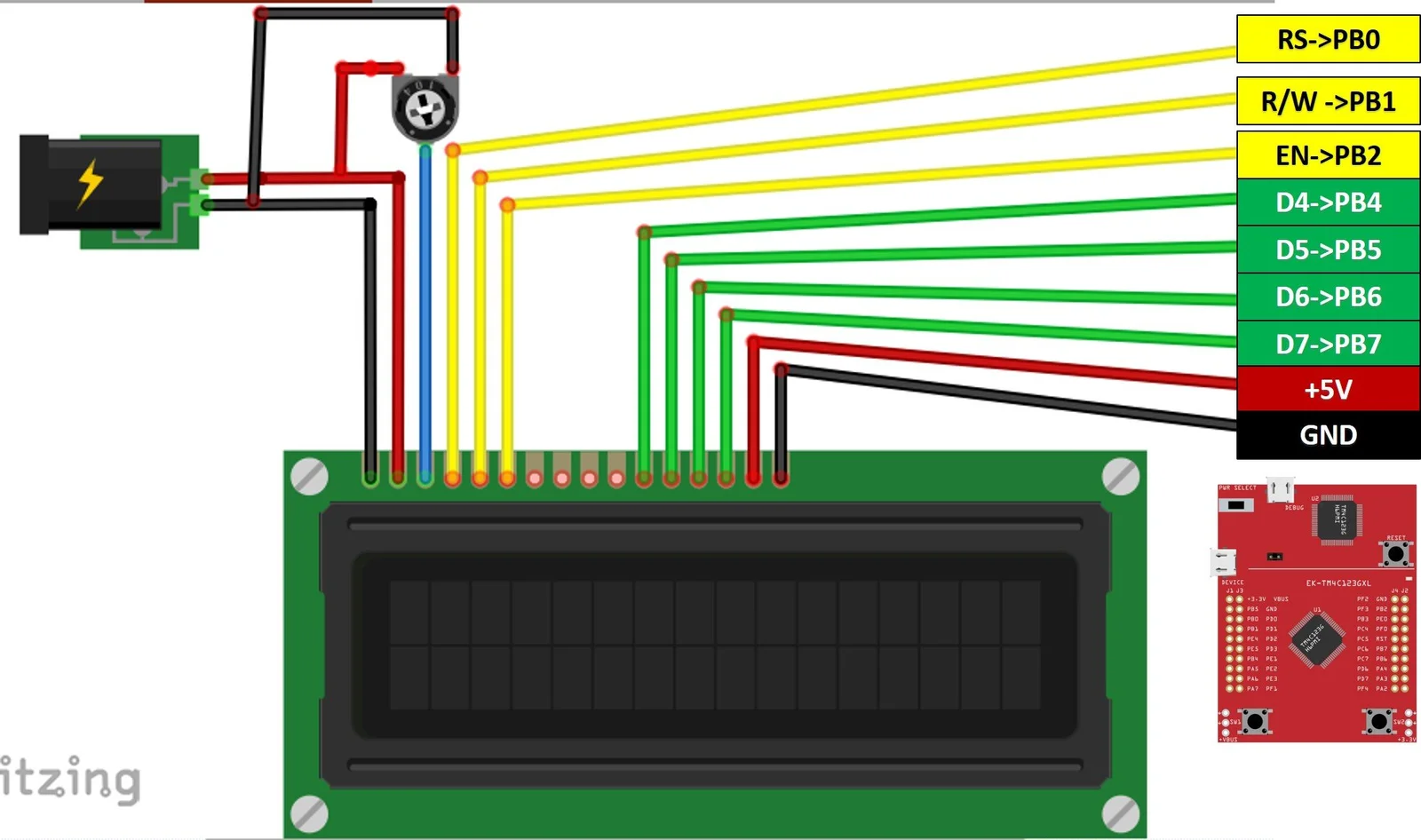

The figure above shows the complete wiring diagram for connecting the 16×2 LCD module to the TM4C123 microcontroller using 4-bit mode. The connections are:

- Power: VDD to VBus, VSS to Ground, V0 to contrast potentiometer

- Control: RS to PB0, E to PB2, RW to Ground (write-only)

- Data: D4-D7 to PB4-PB7 respectively

- Backlight: A to VBus, K to Ground

The contrast potentiometer (typically 10kΩ) allows adjustment of the display visibility - rotating it changes the voltage on V0 pin between 0V and VDD.

The following code demonstrates a complete LCD driver in 4-bit mode with initialization, command/data transmission, and text display functions.

#ifndef LCD_H

#define LCD_H

#include "TM4C123.h"

// LCD pin definitions (connected to PORTB)

#define RS (1 << 0) // PB0

#define RW (1 << 1) // PB1

#define EN (1 << 2) // PB2

#define DATA_MASK 0xF0 // PB4-PB7

// Function prototypes

void LCD_Init(void);

void LCD_Command(unsigned char cmd);

void LCD_Data(unsigned char data);

void LCD_Clear(void);

void LCD_SetCursor(unsigned char row, unsigned char col);

void LCD_Print(char *str);

void delay_us(int us);

void delay_ms(int ms);

#endif#include "lcd.h"

#define CYCLES_PER_US (SystemCoreClock / 1000000u)

//====================[ SysTick Delay Functions ]====================

void SysTick_Init(void)

{

SysTick->CTRL = 0;

SysTick->LOAD = CYCLES_PER_US - 1; // 1us delay at 50MHz

SysTick->VAL = 0;

SysTick->CTRL = 0x5; // Enable with system clock

}

void delay_us(int us)

{

SysTick->LOAD = (CYCLES_PER_US * us) - 1;

SysTick->VAL = 0;

SysTick->CTRL = 0x5; // Enable with system clock

while ((SysTick->CTRL & 0x10000) == 0);

SysTick->CTRL = 0;

}

void delay_ms(int ms)

{

while (ms--)

delay_us(1000);

}

//====================[ LCD Helper Functions ]====================

void LCD_EnablePulse(void)

{

delay_us(1);

GPIOB->DATA |= EN;

delay_us(1);

GPIOB->DATA &= ~EN;

delay_us(1);

}

void LCD_SendNibble(unsigned char nibble)

{

// Send nibble to PB4-PB7

GPIOB->DATA = (GPIOB->DATA & ~DATA_MASK) | ((nibble << 4) & DATA_MASK);

LCD_EnablePulse();

}

//====================[ LCD Initialization ]====================

void LCD_Init(void)

{

// Enable clock to PORTB

SYSCTL->RCGCGPIO |= (1 << 1);

while ((SYSCTL->PRGPIO & (1 << 1)) == 0)

;

// Configure PB0 (RS), PB1 (EN), PB4-PB7 (data) as output

GPIOB->DIR |= RS | RW | EN | DATA_MASK;

GPIOB->DEN |= RS | RW | EN | DATA_MASK;

GPIOB->DATA &= ~(RS | RW | EN | DATA_MASK); // Clear all

SysTick_Init();

delay_ms(50); // Wait for LCD to power up

// Initialization sequence (8-bit interface mode to start)

LCD_SendNibble(0x03);

delay_ms(5);

LCD_SendNibble(0x03);

delay_us(150);

LCD_SendNibble(0x03);

delay_us(150);

LCD_SendNibble(0x02); // Set 4-bit mode

delay_us(150);

// Now in 4-bit mode: use full commands

LCD_Command(0x28); // Function set: 4-bit, 2 lines, 5x8 dots

LCD_Command(0x0C); // Display ON, Cursor OFF

LCD_Command(0x06); // Entry mode: increment cursor

LCD_Command(0x01); // Clear display

delay_ms(2);

}

//====================[ LCD Command/Data API ]====================

void LCD_Command(unsigned char command)

{

GPIOB->DATA &= ~RS; // RS = 0 for command

delay_us(1);

LCD_SendNibble(command >> 4); // Upper nibble

LCD_SendNibble(command & 0x0F); // Lower nibble

delay_ms(2);

}

void LCD_Data(unsigned char data)

{

GPIOB->DATA |= RS; // RS = 1 for data

delay_us(1);

LCD_SendNibble(data >> 4);

LCD_SendNibble(data & 0x0F);

delay_ms(1);

}

void LCD_Clear(void)

{

LCD_Command(0x01);

delay_ms(2);

}

void LCD_SetCursor(unsigned char row, unsigned char col)

{

unsigned char address = (row == 0) ? 0x80 + col : 0xC0 + col;

LCD_Command(address);

delay_ms(1);

}

void LCD_Print(char *str)

{

while (*str)

{

LCD_Data(*str++);

}

}

#include "TM4C123.h"

#include "lcd.h"

int main(void)

{

LCD_Init();

LCD_Clear(); // Ensure display is clear

LCD_SetCursor(0,0); // Set cursor to beginning

LCD_Print("ENCS4110 Lab");

while(1)

{

}

}Code Explanation

Initialization Sequence

The LCD_Init() function implements the complete 4-bit initialization:

- Enables GPIO PORTB clock and configures pins as outputs

- Waits 50 ms for LCD power-on stabilization

- Sends

0x03(upper nibble) three times with delays (8-bit mode reset) - Sends

0x02(upper nibble) to switch to 4-bit mode - Sends configuration commands:

0x28(4-bit, 2 lines),0x0C(display on),0x06(entry mode),0x01(clear)

Nibble Transmission

The LCD_SendNibble() function:

- Masks out current data bits (PB4-PB7)

- Places the 4-bit nibble on PB4-PB7 (shifted left by 4)

- Generates enable pulse: delay → E high → delay → E low → delay

Command vs. Data

LCD_Command(): Sets RS=0, sends upper nibble, sends lower nibbleLCD_Data(): Sets RS=1, sends upper nibble, sends lower nibble

Cursor Positioning

The LCD_SetCursor(row, col) function calculates the DDRAM address:

address = (row == 0) ? 0x80 + col : 0xC0 + col;Then sends the address as a command.

String Printing

The LCD_Print(str) function iterates through the string and sends each character using LCD_Data().

Tasks

Task 1: Display Your Name and ID

Update the main program to display your name on the first line and your student ID on the second line of the LCD.

Requirements:

- Clear the display

- Set cursor to line 1, column 0

- Print your name (up to 16 characters)

- Set cursor to line 2, column 0

- Print your student ID

Hint:

LCD_Clear();

LCD_SetCursor(0, 0); // Line 1

LCD_Print("Your Name");

LCD_SetCursor(1, 0); // Line 2

LCD_Print("ID: 1234567");Task 2: Button-Controlled Name Scrolling

Write a program that displays your name on the LCD and allows the user to scroll the text left or right using the two on-board push buttons (SW1 and SW2).

Requirements:

- Display your name on line 1

- Configure SW1 (PF4) and SW2 (PF0) with GPIO interrupts (falling edge, internal pull-up)

- When SW1 is pressed: Shift display left (command

0x18) - When SW2 is pressed: Shift display right (command

0x1C) - The display should not scroll automatically; only respond to button presses

Task 3: Bidirectional Continuous Scrolling

Write a program that displays your name on line 1 and your student ID on line 2, with continuous scrolling in opposite directions after a button press.

Requirements:

- Display your name on line 1 and ID on line 2

- Initially, the display is static (no scrolling)

- When SW1 is pressed, start continuous scrolling:

- Line 1 scrolls right

- Line 2 scrolls left

- Pressing SW1 again stops the scrolling

- Use a timer interrupt to handle the scrolling at a fixed interval (e.g., every 500 ms)